The Importance of Quality Control in Concrete Pumping

In the construction business, concrete pumping is a vital procedure that makes it possible to precisely and efficiently put concrete in a variety of constructions. The quality of concrete used is crucial to the endurance and durability of any structure, whether it is a residential home, business complex, or infrastructure project. Quality control is essential in ensuring that the concrete being pumped fulfills the highest requirements. This blog post will examine the value of quality control in concrete pumping and go over the important factors that contractors and builders need to think about in order to get the best outcomes.

Concrete Pumping’s Role

Prior to exploring the significance of quality control, it is imperative to comprehend the function of concrete pumping in the construction industry. One of the most important building materials, concrete, is usually delivered semi-liquid to the construction site. Concrete must be moved from the delivery truck to its final location in order to be precisely placed within formwork, molds, or other structural components.

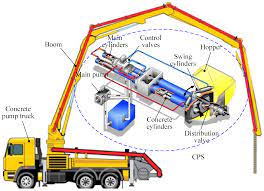

A logistical answer to this problem is concrete pumping. To move the concrete effectively, specialized machinery known as concrete pumps is used. Boom pumps and line pumps are the two main varieties of these pumps. Line pumps are more appropriate for smaller-scale applications, while boom pumps are usually utilized for larger projects and have a substantially wider reach. Throughout the process, quality control is crucial regardless of the kind of pump being utilized.

The Importance of Quality Control

1. Structure and Coherence

Ensuring the structural integrity of the completed building or infrastructure is one of the most important reasons to apply strict quality control procedures in concrete pumping. Concrete’s composition and curing process have a direct impact on the material’s strength and longevity. The total strength of the structure may be compromised by irregularities or flaws in the concrete mix, which could later cause costly repairs and safety risks.

2. Economy of Cost

Retaining quality control in the pumping of concrete can also help construction projects operate more economically. Concrete mixes of superior quality are less prone to early wear and strain, cracking, and spalling. These problems may necessitate costly upkeep and repairs, raising the project’s ultimate cost. Builders can prevent these needless costs by making an upfront investment in quality control.

3. Impact on the Environment

It is well known that the energy-intensive process of manufacturing cement contributes significantly to the environmental impact of producing concrete. Low-quality concrete can lead to increased material waste, which raises a project’s environmental impact. By guaranteeing that concrete is mixed and used effectively, proper quality control procedures can help minimize waste by reducing environmental damage.

Important Aspects of Concrete Pumping Quality Control

Now that we know the importance of quality control in concrete pumping, let’s examine the essential factors that contractors and builders need to take into account in order to uphold high standards.

1. Blend Design and Evaluation

The right mix design is the first step to guaranteeing high-quality concrete pumping. For the desired strength and durability, this entails figuring out the ideal ratios of cement, aggregates, water, and admixtures. The mix design process should consider various elements, including the project parameters, the environment, and any particular performance needs.

To ensure that concrete mixtures fulfill the required design specifications, testing must be done on a regular basis. Air content, slump, and compressive strength tests are a few examples of test types. Rigorous testing and a well-established mix design work together to prevent variances in the quality of the concrete.

2. Equipment Upkeep

To get consistent results, the quality of the concrete pumping equipment is equally crucial. To avoid malfunctions and guarantee safe and effective operation, routine maintenance and inspection of pumps and associated equipment are essential. This include inspecting for damage, changing out worn-out components, and calibrating machinery to ensure precise concrete placement.

3. Certification and Training for Operators

Pumping concrete is a very specific job that needs to be performed by operators who are certified and trained. It is imperative that operators possess a comprehensive comprehension of the machinery, safety procedures, and optimal techniques for pumping concrete. Employing experts who possess the necessary credentials guarantees that the concrete is pumped accurately, reducing the possibility of mistakes or mishaps.

4. Respect for Codes and Standards

When it comes to quality control in concrete pumping, following construction rules and industry norms is crucial. These standards include instructions on how to use supplies, tools, and methods correctly. Adherence to established guidelines guarantees that the building endeavor satisfies safety and quality prerequisites.

5. Plans for Quality Control and Assurance

A proactive strategy to guarantee the quality of concrete pumping is to create a thorough quality assurance and control plan. These blueprints delineate the protocols, accountabilities, and milestones during the building phase. Such plans must include regular testing, documentation, and inspections.

6. Weather and Temperature Considerations

Weather and temperature have an impact on concrete. Extreme temperatures can have an impact on the curing process and setting time. To guarantee the best outcomes, quality control procedures should include these variables and make any necessary modifications to the mix design or placement schedule.

7. Interaction and Arrangement

All parties involved, including the construction crew, the pump operator, and the supplier of the concrete, must effectively coordinate and communicate with one another. To avoid misunderstandings and to make sure that everyone is aware of the expectations and requirements of the project, clear communication is essential.

Suggested Use of Professional Services

In conclusion, it is impossible to exaggerate the significance of quality control in the pumping of concrete. It is a crucial element that affects the construction projects’ cost-effectiveness, environmental impact, and structural integrity. Hiring experts in concrete pumping Charlotte and quality assurance is highly recommended if you want to guarantee that your building project receives the best possible quality control.

Expert concrete pumping services offer not just the technical expertise but also the equipment and experience needed to produce consistently excellent outcomes. You may lower the chance of mistakes, shorten project timelines, and eventually complete construction projects that are secure, long-lasting, and reasonably priced by working with knowledgeable experts.

In summary, quality control in the concrete pumping industry is a complex process that includes a range of activities, from operator training and standard adherence to mix design and equipment maintenance. Builders and contractors can guarantee the success of their projects and provide structures that satisfy the highest safety and environmental standards while also standing the test of time by placing a high priority on quality control throughout the construction process.